Sustainable Circular Design and System Transitions.

Background

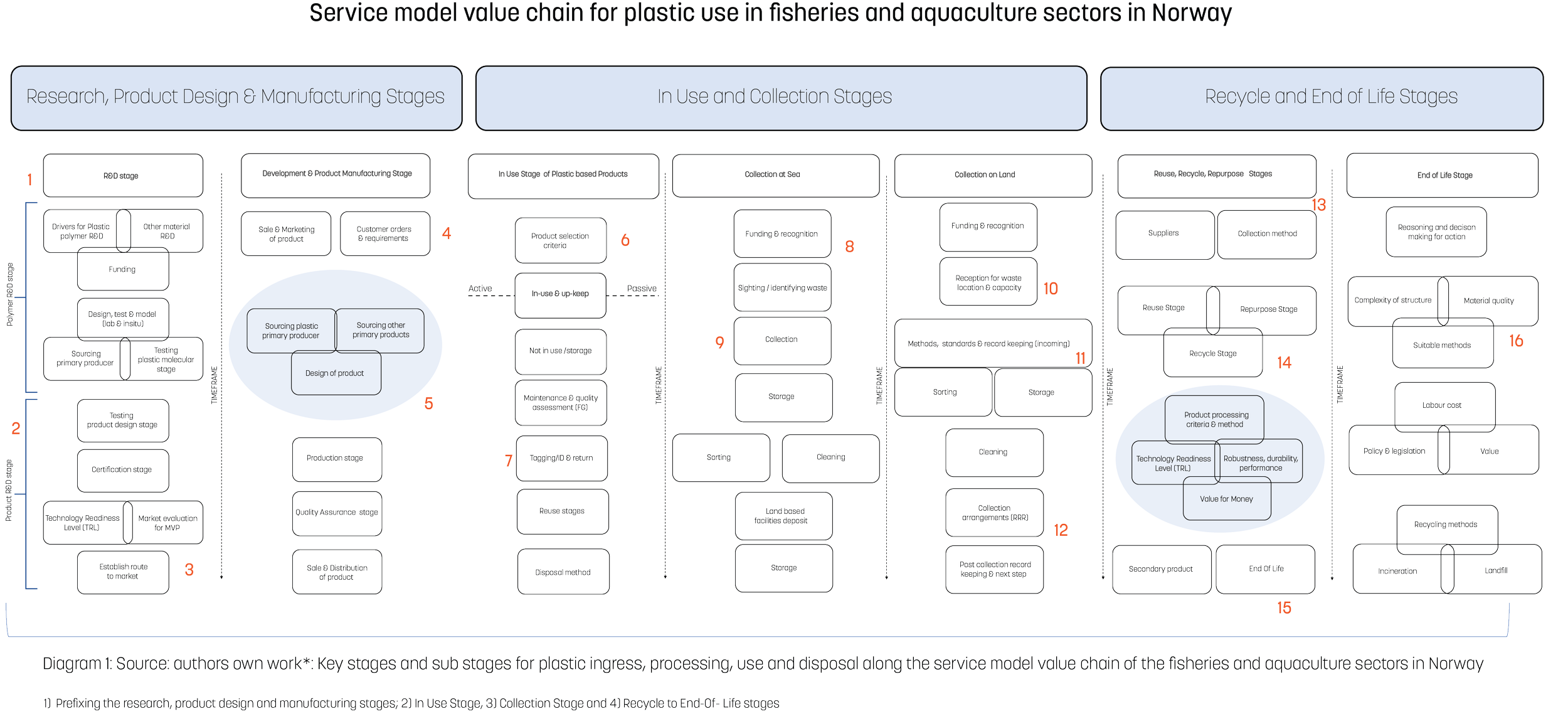

This workshop is the second in a series of activities which seeks to understand plastic pollution in the Aquaculture and Fisheries sectors in Norway. Workshop 2 specifically seeks to build upon workshop 1 (understanding the service model value chain and the ‘journey of plastic’) and develop shared visions, objectives and key principles for a more sustainable circular value chains.

This workshop draws from the Systems Design Approach (SDA) applying various tools and techniques which harness existing knowledge from multi-stakeholders and enable vision work for future more circular scenarios (Costa Junior et al, 2019). The approach undertaken enables the integration of various aspects from several but complementary theoretical frameworks, e.g., Regional Innovation Systems (RIS). This approach offers a more thorough grounding of the insights and narrative surrounding the development of service model transitions.

New service and business models are seen as key in sustainable circular economic (SCE) adaptation and transitions strategies (Raworth, 2017; Robert and Geels, 2019). Businesses and related service models are heavily influenced by the region(s) within which they operate (Roberts and Geels, 2019). Of importance is our ability to frame the activities in ‘action spaces’, namely regional transition spaces (Roberts and Geels, 2019; 2020; De Propris and Bailey, 2021). For this we draw from the RIS and Multi Level Perspectives (MLP) and transition pathway literature (Isaksen et al, 2019). These technical scientific approaches are fine-tuned to unravel complexity such as plastic pollution in the fisheries and aquaculture sectors. Many aspects from this regional innovation space have been identified in workshop 1 (e.g., leadership, governance, collaboration & agency for change, support structures, operational best practice, the importance of knowledge exchange). When combined with other knowledge creation areas (e.g., material science) and the SDA approach, complex situations and knowledge can be managed in ways that engender discussion across varying knowledge spaces and practices (Costa Junior et al, 2019).

The focus is to gain a deeper, more granular understanding of plastic use and multilevel configurations as experienced by the sector actors across the spatial dimensions (global, national, regional, local). This entails specific insights to materials, technology, innovation and business trends and practices. Of importance is the product and service model development including the material properties. Workshop 1 identified that product testing and quality control for circularity should go beyond current polymer and product design parameters (durability, robustness and toxicity standards) (Krauklis et al, 2021). This stage should incorporate more robust communication systems with recycling and end of life actors, accountability and quality control of the polymer and products used, and be set to Norwegian standards for circular design or ‘green design’ (Palmer-Abbs et al, 2022). Much discussion is required to debate the mitigation strategies required for current materials and the complexity of product design in order to transition to more circular products. This requires knowledge on scientifically proven materials that achieve better outcomes in terms of plastic pollution mitigation. Identifying and tackling this problem for the ‘worst cases’ requires material flow analysis (MFA) (Deshpande and Haskins, 2020). We have two junctures where this evidence is investigated. The first is marine waste collection, which has identified the largest by volume contributors to plastic waste in Norway (Brodbeck, 2016). The second is tracking the flow of plastics across the fisheries and aquaculture sectors. Good progress is evident in the fisheries sector (ibid), but the aquaculture sector is less understood. Therefore, establishing the exact details of plastic loss and ingress to the environment from the sectors’ service model value chains is ongoing.

However, we can identify and tackle the highest contributors by volume from the data on marine waste. With a coastline of 25,000 km and over 4500 ports[1] (Nofir, 2016; Skar et al, 2020), no other European country exhibits the challenges evident in Norway in terms of distance and points of entry to the sea (EC, 2019). This is a challenge in terms of accessing marine debris which naturally collects (ocean currents and FG waste hot spots) in difficult to access spaces. 70% of this plastic-based marine waste is attributable to Norwegian activities. Of this, Ropes, trawl nets, seines and pots are known to be a particular issue (Brodbeck, 2016). Whilst Norway has some of the world’s leaders in recycling (Nofir, Oceanize, etc), challenges in accessing the marine waste coupled with the incumbent principles of Eco design Directive (EC, 2009) engender a strong focus on early preventive measures. The focus on early interventions in the value chain (product and material design, loss prevention) seeks to prevent the worst materials (by volume) entering the value chain, extended product life and preventing losses of products (e.g., better design, maintenance and tagging equipment for returns) (Palmer-Abbs et al, 2021). Reduction of plastic-based waste must be optimised, and only when these avenues have been exhausted should we look to collection, recycling, reuse, repurposing and if more environmentally friendly, end of life options such as incineration (ibid). Countries (in particular small Asian nations) with less well-developed waste services have opted to revert to more natural based products, such as jute for ropes and crab/lobster pots. Discussions with Norwegian recycling companies confirm that bulky, difficult to transport products such as pots are prohibitive to recycle (cost and transport). This raises the question that certain products may be suitable for material substitution. Substitution of more natural materials should be considered in conjunction with other materials for relevant products.

Just transition and resilience include and rely upon inclusive societal change. Whilst the focus of this project is the service model value chain improvements, long term change relies upon an informed and proactive society. Therefore, future proofing of decision making, adaptivity and continued advances towards circularity relies on an educated populace. To this end an adaptive system should also include knowledge exchange, education and training across all of society.

Collective resolve of plastic pollution mitigation must adhere to sustainability credentials such as the ‘displacement effect’. It is not acceptable to ‘export’ problems or create problems from our activities – wider considerations are required to understand global-local implications of choice making, e.g., in construction ISO 14001 monitors impacts of mining and production on imported products.

Based on these findings and more in-depth insights from workshop 1 (Palmer-Abbs et al, 2021), workshop 2 seeks to build on the previous service model value chain mapping, state of the art (e.g., material science, material flow analysis, life cycle analysis, etc). We also build on learnings such as the role of key actors, strength of agency, improved collaboration, leadership, governance, support structures and resilience in preventing plastic pollution and creating just transitions for business and the wider society (Miörner, J, 2020; Isaksen et al,2018; Beer et al, 2021, Kristensen et al, 2022; Roberts and Geels, 2018).

Using a systems analysis approach this workshop sought to co-develop a vision for a more sustainable circular value chains, define key principles for what this could look like, and explore transition actions in reaching these goals. The following themes were considered based on workshop 1 findings: materials, design, roles and responsibilities, governance and leadership and society & change.

[1] If we take the definition of a port as a place where you can enter the sea, Norway has over 4500 ports (Skaar et al, 2020; EC, 2019a; Nofir, 2016)

WP3 Co-production: A reflection on workshop 1: key findings

In workshop 1 participants explored and co-produced their agreed vision of the sectors’ current service value chain model critiquing shortcomings and deciphering areas for change (a full copy of this report can be found here .Key points were:

Policy & Governance: The incoming legislation and policies (EPR & PPP) require strong leadership and collaborative working if Norway is to fully benefit from the intent of these standards. Whilst policymakers have a significant role to play in this progress, there is an opportunity for governance innovation in how Norway approaches this ‘transition landscape’. The use of collaborative partnerships in developing new systems and associated services is highly recommended.

Responsibility & Ownership: There is much good will among actors across the value chain to support great circular practices. However, it remains unclear how the EPR and PPP will filter through the system for the industries and what this will entail. Further discussion is required to see what options and opportunities are available for the industry to collectively make the step changes for CE transitioning. Assurance of what is expected from industry and the public sector will provide the assurance they need to viably manage system change in ‘real-time’.

Multi-Generational behaviour and choices: Currently there is a divergence between younger generations’ more environmentally aware customers and the more traditional thinking customers for the industry. This poses a problem for suppliers as they juggle customer choice during a state of transition. However, it also offers opportunity to speed up the transition towards more environmentally friendly products through incentives and education awareness raising activities. These should be carefully attuned to the users, their availability, and ability to access additional information to ensure success.

Design practices & decision making: A more joined-up system for design and production of products is required to achieve greater circularity in fishing and aquaculture gear for the fisheries and aquaculture sectors. This should be based on sound science and best existing and new products which includes LCA accreditation. These activities will need to be linked to training and education for policy actors, producers, suppliers, users and RRR and end of life practitioners. This will ensure all actors understand the new design requirements, opportunities and obligations. Due to the scale of change required, step-change criteria will be needed for short-, mid- and long-term changes. Mechanisms to support this change (policy/industry dialogue, support systems and accreditation systems) accounting for appropriate timeframes against these changes are required. It is therefore pertinent that a system to manage and coordinate such a change should be designed and managed – possibly by a third party – this could be an independent body comprising academia, industry and policymakers.

Designing out problems: There are some very good examples of existing recycling practices in Norway, e.g., nylon-based FG to secondary product. However, more needs to be done for other problematic materials. Further consideration is required at the R&D and product design stage to reduce problematic materials and complex design of FG. Interception of the highest impact products earlier in the service model will reduce the impact of plastic across the whole value chain and enable more robust businesses in the later stages of the value chain, e.g., RRR and EOL.

Quality assurance: Current product design criteria in the industries is based on technical performance criteria. Whilst it is essential to uphold these standards, there is a current drive from industry and their customers to incorporate more circular standards. The optimum stage of the value chain to pursue this is the R&D and production stage of the gear, e.g., LCA, sound scientific evidence for marketing, types of polymers and recyclability, circular design features, etc.

Systemic Performance & Standards: Systemic change and governance is required to achieve more circular economic practices across the service model value chain. These include but are not limited to R&D, CE product standardisation, CE procurement, policy support mechanisms, accreditation systems, waste service methodology, waste service infrastructure and RRR/EOL protocols. There are many key actors who have a critical view of what, and how, this should look. Further development of this will be explored in the 2nd workshop.

In Use and maintenance: Upkeep and maintenance of fishing and aquaculture gear is essential for extending the life of equipment. Variability in the quality and cost of services needs to be more transparent, accurate and informative for users to ensure best practice is upheld. Encouraging more circular decision-making practices in this area will need support in terms of information but it is also likely that other support mechanisms will be required, e.g., tax incentives to reward CE practices.

Collection protocols and management: Careful consideration needs to be given to what the ‘Norway collection and management model’ for waste gear should look like. This should take cognisance of geography, topography, infrastructure and behaviours of the industries, and how best to optimise more circular design of this service. Existing innovation in the sector illustrates great potential for new ideas.

Protocols for Recycle, Reuse & Repurpose and EOL: The circular economy seeks to maintain resources in primary and secondary states for as long as possible. Currently the route of total Norwegian waste from fishing and aquaculture gear is haphazard and subject to multiple decision makers. Whilst some good practice is in place there needs to be a standardised approach to waste management and what is the optimal route for waste based on circularity rather than ‘just best option at the time’, e.g., decision making protocols between recycling and repurpose or recycle and end of life.

Validation and documentation: It was acknowledged that marine waste is multiscalar (local, national, global) and complex in their nature. However, improving domestic management of the sectors’ waste and showcasing best practice in Norway will support transitions elsewhere e.g., Environmental Performance Documentation (EPD). Some early Norwegian innovators, such as Nofir, have designed such a system for their activities in recycling, reuse and repurpose. In turn we suggest that lessons can be learnt from other nations and industries who have gone through similar transitions, e.g., the UK construction waste management scheme WRAP.

Culture and credentials: The drive to become more sustainable and circular is apparent across society and the industry. This is pushing the need to evidence product and service performance. However, it would be remiss to assume all sections of society are moving at the same pace and with the same focus. Taking the lead from the early societal leaders in seeking more circular products and practices should be used to accelerate the move to more circular practices. Marketing of the results and impact is likely to engender wider support for CE practices through consumer purchasing, etc.

New Value Chain section: It was noted that there was a stage missing in the R&D section, namely the interface between the producer/supplier side of the value chain and what polymers and design principles enter at the R&D stage of FG design. Key factors include the influence of other national policies (cross-border decision-making) on plastics standards based on those of the ‘supplier nations’, e.g., China and India. In general Norway was seen to have little control over what type of products and quality were entering the Norwegian market. For instance, Asia is seen as more production-focused while Norway requires a Life Cycle Analysis (LCA) approach.

WP3 Co-production:Objectives of workshop 2

T3.2 Co-producing key principles for circular economic practices across the service model value chain of the fisheries and aquaculture sectors.

Using systems and design thinking, the co-production Workshop 2: will seek to:

Objective 1: Build a better understanding of the thematic outputs from workshop 1 of the key issues which underpin the transitioning to more Circular Economic Business and Service Models.

Objective 2: Co-create what this vision may look like and how we could transition to meeting this objective.

Objective 3: Decide on key points from workshop discussions and agree upon a set of key principles for more Circular Economic Business and Service Models in the fisheries and aquaculture sectors.

Materials [Quality of materials; Resource and procurement; Quality and controls measures; RRR & EOL considerations]

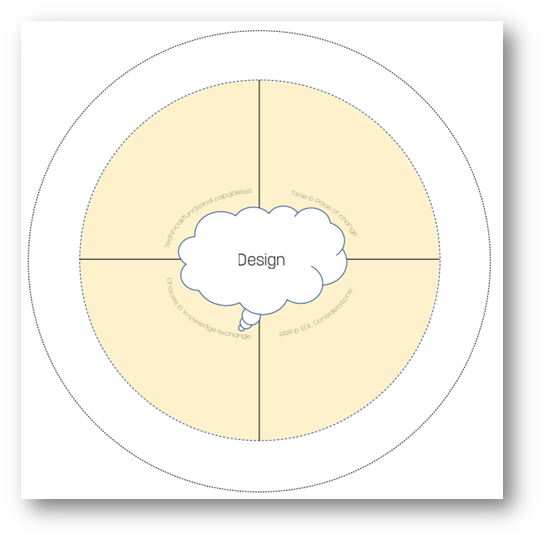

Design [technical /functional capabilities, Time & pace of change, Choices & knowledge exchange, RRR & EOL consideration]

Governance and Policy [Legislation, Objectives, Tools & Instruments, Business models (strategic level)]

Roles and Responsibilities [Business organisation structures/models, Industry role, Public sector role. Collective resolve (public/private & R&D relationships)]; and,

Society and Change [Education, Training and society, Circular purchasing, Media & research]

Who was invited and why: Representatives from project partners and other relevant projects were invited. A total of 32 participants covering all stages of the service model value chain participated. User membership organisations represented the fishermen and aquaculture practitioners. (This stakeholder group are also being interviewed and surveyed separately as this is the best communication approach). Five groups were pre-organised to ensure balanced configurations by sector, gender, expertise and attributes. Groups were roughly 7-8 people with an experienced facilitator leading the tasks.

Method and Tools

Objective 1: Activity 1: To collaboratively develop key factors which underpin themes and sub themes in developing more circular practices in sectors.

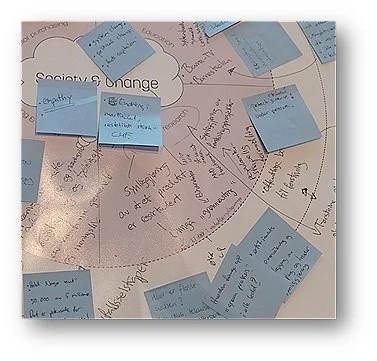

Drawing from insights from workshop 1, and ensuing project work, Activity 1 used five thematic basemaps with sub themes which were specifically designed to promote discussion, debate and collaborative decision making in pursuit of deeper insights about the phenomena. Core and sub themes were:

Activity 1: Task 1: Working in groups for 20 minutes (rotate to next group after 20 minutes) to discuss themes and sub themes, writing key points onto basemaps, sticky notes or relaying points to facilitator who can note take.

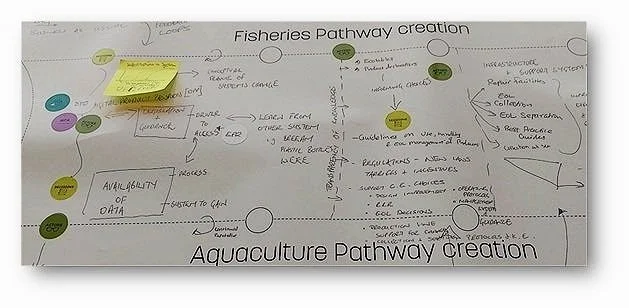

Objective 2: Activities 2 & 3 Visioning and transition pathway scoping

Objective 1: To develop a vision for future more circular practices in the thematic area for the fisheries and aquaculture sectors’ service value chain model.

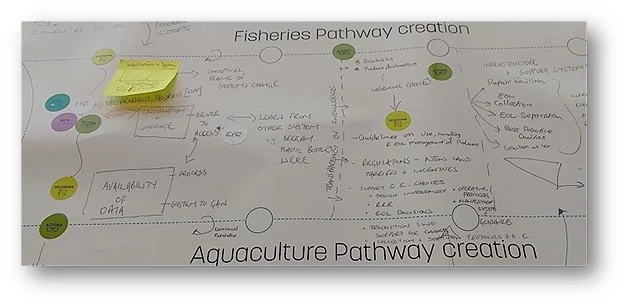

Activity 2 and 3 built upon these discussions with one core group most suited to the topic under discussion, e.g., materials group work enlisted material scientists, recycling experts, policy and producers. Each group worked with their thematic visioning and transition pathway basemaps discussing, mapping and future casting the needs of the sector in transitioning to more circular practices.

Activity 2: Task 2: Short discussion on key points from thematic basemap and what this means for a future vision on this theme.

Activity 2: Task 3: Write what this vision could be for this theme in moving the sectors towards circular economic practices.

Activity 2: Task 4: Map storyline of the journey from the basemap factors to achieving this vision. (E.g., where do events occur in terms of steps and timing of activities: ref: project service model value chain, use notetaking and stickers to map key actions, points, needs, etc).

Objective 3: Activity 3: To agree what key factors should be used to inform a set of key principles for circular economic practices in the sectors.

Activity 3: Task 5: Using the wall analysis technique, groups decided on the key principles they felt their theme required, presenting these key principles to wider workshop participants, explaining why this has been chosen, what it means, and how you expect it will inform the wider goal to achieve more circular practices in the sectors.

The visual tools are now presented:

Fig 1: Source: Palmer-Abbs (2023): Example of thematic basemap: graphic illustration by Marta Anna Løvberg

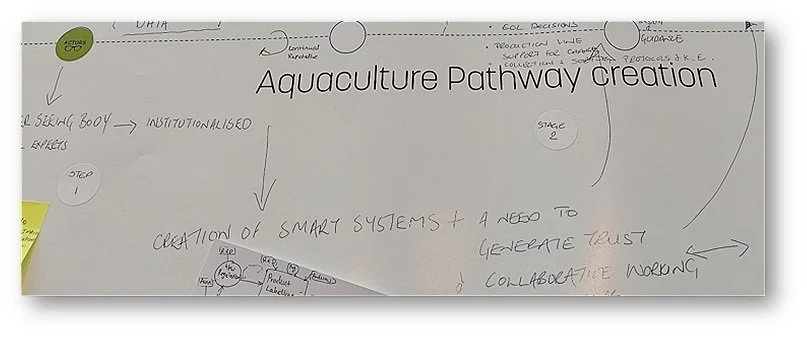

Fig 2: Source: Palmer-Abbs (2023): Visioning and transition pathway basemap graphic illustration by Marta Anna Løvberg

Fig. 3 Source: Megan Palmer-Abbs (2023) Service Model Value Chain for use of plastics in the fisheries and aquaculture sectors: designed Graphic illustration by Marta Anna Løvberg

What we found

Mitigating the impact of plastic-based pollution from equipment and services used in the fisheries and aquaculture sectors cannot be resolved by a few simple changes in the service model value chain. It requires change across the whole system, e.g., governance and leadership, operational adjustments and new or improved products and services which are based on sound science and knowledge exchange involving all sectors, support services and actors. This multilevel change must be based on the key principles of sustainable circular economy (SCE) – in other words adopting the key principles of sustainability (environment, economic and social) and the boundary principles of circular economy. The coherent and transparent operationalisation of these key principles is vulnerable to human folly, at best misunderstood and poorly represented, but all too often misused resulting in technocratic or economic-centric solutions and ‘greenwashing’. Environmental stability, including plastic pollution, is at a critical juncture, time is not on our side, therefore we can no longer leave mitigation measures to ad hoc decision making. Changes should be based on sound science, be socially just and embedded across society, not just the business community.

Just transition and resilience include and rely upon inclusive societal change. Whilst the focus of this project is the service model value chain improvements, long term change relies upon an informed and proactive society. Therefore, future proofing of decision making, adaptivity and continued advances towards circularity relies on an educated populace. To this end an adaptive system should also include knowledge exchange, education and training across all of society.

Collective resolve of plastic pollution mitigation must adhere to sustainability credentials such as the ‘displacement effect’. It is not acceptable to ‘export’ problems or create problems from our activities – wider considerations are required to understand global-local implications of choice making, e.g., in construction ISO 14001 monitors impacts of mining and production on imported products.

Workshop 1 identified that core to sound decision making is the use of accurate knowledge, the right system, and space for guided and applicable innovation that delivers sustainable circular economic changes. Based on this premise, a set of visions of what an adjusted system should entail could be:

VISIONS

TRANSPARENCY - PEOPLE NEED TO SEE FIRST HAND THE CONSEQUENCES OF A CERTAIN CHOICE.

TO DEVELOP A HOLISTIC SYSTEM WHICH AVOIDS NEGATIVE IMPACT ON OTHER ASPECTS OF SUSTAINABILITY.

A GOVERNANCE SYSTEM GEARED TOWARDS VALUE CHAIN TRANSPARENCY, COOPERATION, AND COMMON NORMS – THROUGH A BALANCED APPROACH TO INCENTIVES AND SANCTIONS.

NON-DETRIMENTAL USE OF PLASTICS TO NATURAL ECOSYSTEMS WHICH ADDS TO THE PRODUCTIVITY OF FISHERIES AND AQUACULTURE

IMPROVE KNOWLEDGE BUT TOGETHER WITH A CHANGE IN ATTITUDES ABOUT DISPOSABLE PRODUCTS.

ALL GEAR AND EQUIPMENT IN FISHERIES AND AQUACULTURE SHOULD BE SUITABLE FOR RECYCLING.

KEY PRINCIPLES

Design dynamic systems for knowledge exchange and decision making.

Enable infrastructure and support systems for effectiveness and efficiencies.

A learning system from feedback loops for alternative design.

Efficient systems and solutions are developed through knowledge-sharing, co-creation, and coordination across the ecosystem

Design knowledgeable institutions to guide change.

Roles and responsibilities are transparent and well-defined.

Actors are empowered and incentivized to fulfil their role.

Limit wear and tear to avoid microplastic contamination to the sea.

Limit leakage of environmental toxins.

Adding of recyclable materials into new products.

Extend lifetime of products.

Key points

Systemic Change towards Sustainable Circular Economy (SCE): As the problem of plastic pollution mitigation is a systemic challenge, change must occur at a suitable systems level. Whilst such change requires a top-down structure, Norway’s highly democratised structure and culture lends itself to a high degree of collaboration and cooperation. A new expert body is recommended that leads in this endeavour and oversees the system change. This expert body or organisation should be formed by leaders and decision makers representing the whole value chain to including academia, public, and private sectors, inclusion of the voluntary (third) sector is desirable. A shared vision of what SCE entails is required with agreed objectives which are implementable. Life Cycle Analysis (LCA) and Material Flow Analysis (MFA) data is considered critical in this endeavour.

A living system: Contemporary ‘wicked’ issues, such as plastic pollution in the marine sector, are dynamic and therefore require an evolutionary system in its resolve. A leadership & standardisation system is required which is embedded within the service model regime. The objective of this system is to generate scientifically sound open access data, standardisation of SCE practices and be a system capable of ‘dynamic learning’ which keeps pace with society and changes in SCE practices (Fig 1). Underpinning this living system will be various policy instruments, tools, incentives & tariffs, standardisation & labelling protocols and best practice knowledge born from collaboration between governance bodies, industry, academic institutes and third sector. The aforementioned collaborative decision-making body is integral to this new system.

Multilevel thinking and doing: Systemic change should be interactive, integral and reflexive of the objectives in pursuit of the final goal. Developing a culture which overcomes siloed short-term thinking and builds for longer sustainable goals is essential. This must be considered at multiple levels (e.g., individual, intra-organisational, regional, national level, international).

Step change and planning: As change will be an evolutionary process, transitions will take many forms, pace and spatial dimensions. An agreed set of objectives, goals and timeframes are required suitable to engineer change yet adequately reflexive and adaptive to the dynamic situation(s).

Governance: There is a clear need for sound governance and leadership in plastic mitigation and management. Governance innovation is almost inevitable and should both encourage and lead collective working and systemic change. As policy is an integral part of multi-level change, it is essential that leadership of SCE transitioning is well thought through, is collective and focused. A good starting point is to lead by example. Government organisations and departments should synergise (by topic area) collective resolve and activities towards SCE, e.g., a holistic approach that cuts across departments (law, policy, services, etc).

Advocates, Actors and Agency: Knowledge and support systems are essential in system transitions. Key to this are individuals and collective bodies (business, universities, public bodies, etc) and their ability to collaborate. The formation of collaboration networks [industry, public sector, civil society and academia] is essential to ensure knowledge and change are endemic across society. The correct levels (e.g., regional, national, international) of decision-making bodies and mechanisms must be determined reflective of cultural norms and suitable in meeting the SCE objective(s).

Innovation for SCE change: The system should engender positive change which is based on sound science. Policy is best placed to support this change, tariffs and incentives should be applied in this respect. Careful navigation of cultural norms and the pace of transitioning must inform the application of such interventions. Too long or short in their application can result in stifled innovation or overreach. Consideration should be given to current policy (short-lived) interventions, which should be reflective of the varying levels and types of innovation required to support the range of transition spaces. Collaboration across all sectors is required.

Drivers: roles and limitations: Policy and associated instruments act as drivers for change (e.g., EU green design, Extended Producers Responsibility (EPR), etc). However, the multiplicity of current policy mixes can be tricky for many to navigate. In addition, the timing of policy can fall short or overshoot the ‘timing’ required to achieve its objectives coherently across society. Policy actors must challenge overall objectives and be vigilant to policy blindness (e.g., over-emphasis or poor balancing of policy mixes). Reflexivity and critical judgements must be constant and based in cultural norms in pursuit of SCE values.

Products & Materials: Sustainable circular design principles (e.g., material quality control, design out complexity and whole life design considerations) must be introduced into product design parameters in order to overcome current product limitations (e.g., current legislative criteria for product design does not include SCE criteria). LCA and MFA must be used to determine the ‘best design approaches’ which are the most sustainable and circular for each product. For example, extensive transportation and then recycling is not always the best LCA option in Norway. Producers must be required to prove their SCE credentials, one consideration could be a product design certificate which labels / certifies a set of credentials, e.g., all materials and quality, design principles and product management details (e.g., design for disassembly, recycling, incineration based on LCA/MFA), etc.

Business models and tools: New business models and tools are often the result of niche opportunities. It is essential that sound science and support infrastructure is open, transparent and suitably available to enable innovation within existing business and open up opportunities for new entries on the market.

The role of Innovation and contribution to appropriate design principles: Carefully assembled design principles are required which guide innovation and SCE outcomes. Both academia and industry are very active in material, product and service design innovation for the sectors. Cognisance of the ‘state of the art’ in current practices should be noted. However, reflection and adjustments may be required if innovation falls short of proven concepts and mitigation measures. LCA and MFA are required to substantiate scientifically sound innovations which improve plastic and material SCE credentials. This process is dynamic, evolutionary and time sensitive. Policy support is required to support such innovation. All levels of society should be actively involved in generating new ideas in pursuit of sustainable circular design, e.g., science, innovation and schools; think tanks and centres of excellence, etc.

Transparency, social justice and ownership: For successful change to occur, transition building must be society-wide, lessons could be learnt from other systems, such as the application of the Building Research Environment (BRE) Green Guide and Building Research Environmental Evaluation Assessment Methodology (BREEAM) and societal learning activities. For example, learning how a system could be developed suitable to support change and the promotion of advocacy and knowledge exchange. Academia and public sector are key in this objective.

Multigenerational Ownership: Education should be developed which is embedded in local cultural norms, be informative on plastic mitigation in the marine sectors, widening scope of waste information from domestic rubbish and recycling to include these sectors, and be a statutory requirement of all funding systems as an agreed outcome. Key sectors could share responsibility, e.g., the food and drinks sector.

A learning society and education: Understanding sound science is pivotal to change and must cross all levels of society. Sustainable Development is core to many education frameworks and gaining momentum in sustainable product, services and sector management practices. Much existing work can be grouped and integrated into future SCE visions and systemic change. However, only by increasing the visibility and openness of information about plastic pollution mitigation will SCE practices improve. This must be multigenerational in nature to deeply embed learnings about the sectors across society.

Just transition and resilience: include and rely upon inclusive societal change. Whilst the focus of this project is the service model value chain improvements, long term change relies upon an informed and proactive society. Therefore, future proofing of decision making, adaptivity and continued advances towards circularity relies on an educated populace. To this end an adaptive system should also include knowledge exchange, education and training across all of society.

Collective resolve: of plastic pollution mitigation must adhere to sustainability credentials such as the ‘displacement effect’. It is not acceptable to ‘export’ problems or create problems from our activities to other localities – wider considerations are required to understand global-local implications of choice making e.g., in construction. If made mandatory for imports, the compliance with the ISO 14001 standard would regulate practices occurring outwith Norway in material production. This approach serves to mitigate the impacts incurred at mining and production at the local level e.g., non-EU countries must be compliant to import.

Illustration 1: is a visualisation of a framework for a new sustainable circular economic system (SCE) for the Fisheries and Aquaculture sectors. It illustrates a new governance body for leading and managing SCE practices, linkages with governance bodies, infrastructure support systems and business. The transition /learning system is core to the aim, offering a dynamic interactive space for transition tools e.g., instruments, guidance, guidelines, standards, labelling, networks and best practice.

Illustration 1: Source: Palmer-Abbs (2023): A framework for transitioning to smart systemic change in the fisheries and aquaculture sectors

[1] Policy Tools & instruments– EPR, etc

[2] New Incentives: SCE design, production line support, RRR-EOL decision making and management protocols

[3] A Set of Guidelines: 1. Use, handling and EOL management of products. 2. Operating protocols (waste, RRR and EOL).3. Management systems and guidance

[4) Best practice guides

[5] Eco-industrial network & best practice 1) Repair facilities 2) RRR/EOL collection 3) RRR/EOL separation

[6] Open system & data generators – e.g., academia, policy makers, industry, NGOs, etc

Thematic analysis

THEME: DESIGN

SYSTEMIC CHANGE: Moving to more sustainable circular practices.

A standardised Circular Economic Approach and System: All products require clear definitions (including circular design parameters) for the industry, coupled with a suitable ombudsman, tariffs, incentives and oversight of effective transitioning to improved standards. The ombudsman should have expert representation from across the whole value chain, time in service and management protocols and objectives for current needs. This body and its objectives should be reviewed as progress is made and ‘mitigation needs’ are further identified. Circular Economic Approaches should be designed into products (design for dismantling, design for recycling, design for elongated life). However, at the individual product level each of these design principles may determine a different or competing design approach. More data from LCA and MFA is required to determine how a product should be redesigned, identifying the best secondary avenue and attributes of the product in meeting this outcome (e.g., designing for reuse will be different from designing for incineration or recycling). This should include product/polymer type(s), behaviour of polymer/product, LCA/MFA and system impact. This assessment is required for existing and new products to determine what improvements are being achieved and how this is improving key objectives for Circular Economic practices, e.g., compare Apples and Pears of the industry and identify best products, services and gaps in the market. A labelling system is required which identifies the details of the products, its components, and how recycling (or recommended secondary activity) can be achieved. All products (old and new) should be required by law to have an EPD with this level of analysis. CE criteria must evidence the ‘best route of action for each product’ from cradle to cradle to inform such choices at key decision points across the value chain (R&D, product design and manufacturing, maintenance, collection & Recycle, Reuse, Repurpose (RRR), incineration & End of Life (EOL)).

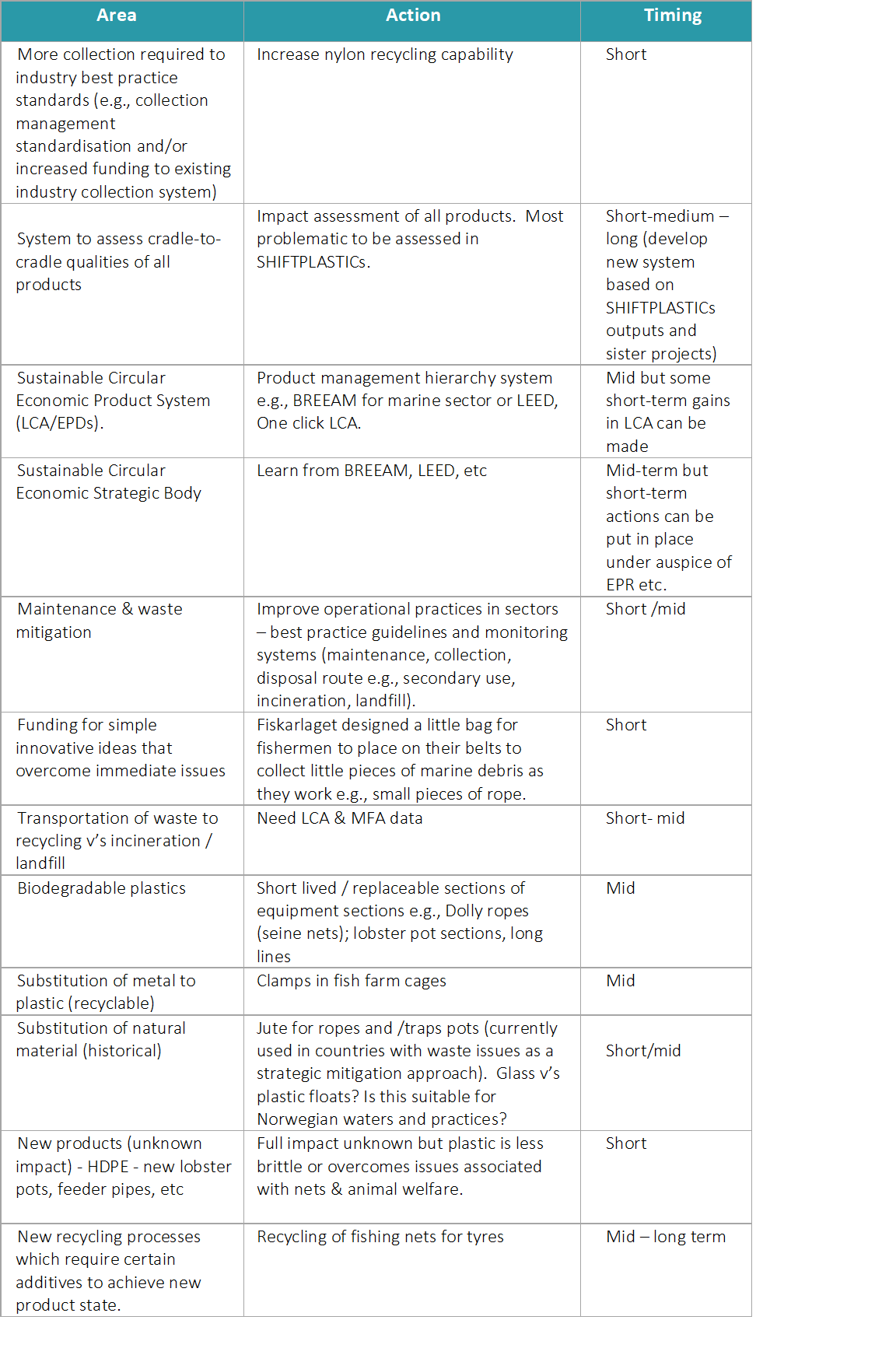

Several short – mid-term opportunities were suggested which may mitigate plastic pollution from current marine sector equipment/gear (See table 1).

New materials are an unknown quantity for those further down the value chain and may impact their current recycled products, e.g., introduction of bioplastics for dolly ropes on seine nets. More information is required to investigate how design alteration will affect current performance, life expectancy and recycling practices.

Time and Pace of Change

There is a need to coherently understand how much change is required technically, in processes and practices? In order to do this we need an overview of

1) What is the problem with the plastic and related product design.

2) What do we want to solve?

3) How is this best achieved – e.g., objective

4) Trade- offs (e.g., CO2 emissions over loss of plastics)

5) What is the right level to manage eco design

Table 1: Palmer-Abbs(2023) Changes in service model areas, required actions and timings

RRR & EOL Considerations

Greater support is required for existing collection systems as these have a proven track record and good results in recycling outcomes. This could be incentives for business to use these systems more for innovation (e.g., via Innovasjon Norge). Such incentives could be money back on next purchase, rebates on landfill tax, etc.

Greater collaboration across the value chain in developing product declaration guides are required to establish a waste hierarchy system for current products. This should be designed to support decision making for the best routes of each product at the RRR and EOL stages (e.g., again learn from the development and application of BREEAM & LCA). This must include new material science outputs (biodegradable plastics, new HDPEs, additives, toxicity, etc).

There is a possibility to use social enterprise (e.g., those out of work and in training) in new business models for the dismantling of more complex gear in Norway. This could adopt a cooperative model whereby individuals can be shareholders and incentivised to work. These can be based more locally to waste collection, be small working groups, and enable the better transportation of voluminous products by reducing their size prior to transportation.

Recycled plastic costs more (in NOK) than virgin plastic to make. Whilst many buyers are interested in the ethos of recycled plastic, the additional cost is a disincentive for them to change their purchasing behaviour. Where recycling is proven to be the best option for plastics from the sectors, incentives or tax deductions are required to drive purchasing opportunities. EPDs/certificates are more common from market leaders for recycled materials and should be held up for all industry actors as a ‘way forward'.

Elongating the life of products is best achieved through appropriate maintenance regimes and the recertification of products. However, as with all product development CE criteria must evidence the ‘best route of action for each product’ from cradle to cradle to inform such choices.

Choices & Knowledge Exchange

Transparency is required in knowledge exchange and across the multi-stakeholder working relationship if the sectors are to move towards more sustainable circular practices. This includes in-depth information on data, processes, outcomes.

Industry requires explicit information to make informed choices about recycling choices (mechanical, chemical, recovery). Labelling was suggested to illustrate origins, uses and secondary choices for products. The recycle triangle and plastic identification (PET) was seen as too generic. A full understanding of the EU LCA information (e.g., GHG, energy, transport, toxicity, etc) should be offered with key advisory notes on best practice for cradle-to-cradle routes. In support f this, consideration should be given to closed loop or more open system recycling options. Much can be learnt from different industries (construction, automaton, clothes, roads) on the most appropriate secondary product uses. These decisions should not add to the problem of waste and pollution. Protocols for these decisions must be based on the aforementioned new sustainable circular economic system and support structures.

It is recognised that the system change under discussion is an evolutionary process and will require many alterations and interventions. One possibility for design change is the funding of Eco designers to work with industry – however this must be closely monitored and based in science to avoid ‘greenwashing’. This point can be addressed in part within the SHIFTPLASTICS project in activities in workshop 3. However, ongoing training courses, product valuation systems, innovation support systems (incl. tax incentives for EPD development and new designs which are evaluated in the system – as mentioned) are also required to shift the market. Ensure feedback loops are in place in the system to enable the evolution of the systemic itself and updating of requirements in keeping with the evolving objectives.

THEME: MATERIALS

Each of the materials in the gear has its purpose and function. To achieve strength or flexibility there is a need to combine several material types. Gears elasticity and floating ability depends on the composition of the materials, this knowledge comes from earlier experiences and is integrated into new design. However, this practice of combining several materials can be problematic for RRR- purposes. Hence, the quality of materials can be discussed in relation to challenges for recycling. A

Most problematic materials, gear/equipment.

From a circularity perspective several materials and gear have limitations. The major concern is nets and equipment that consist of mixed materials, for example:

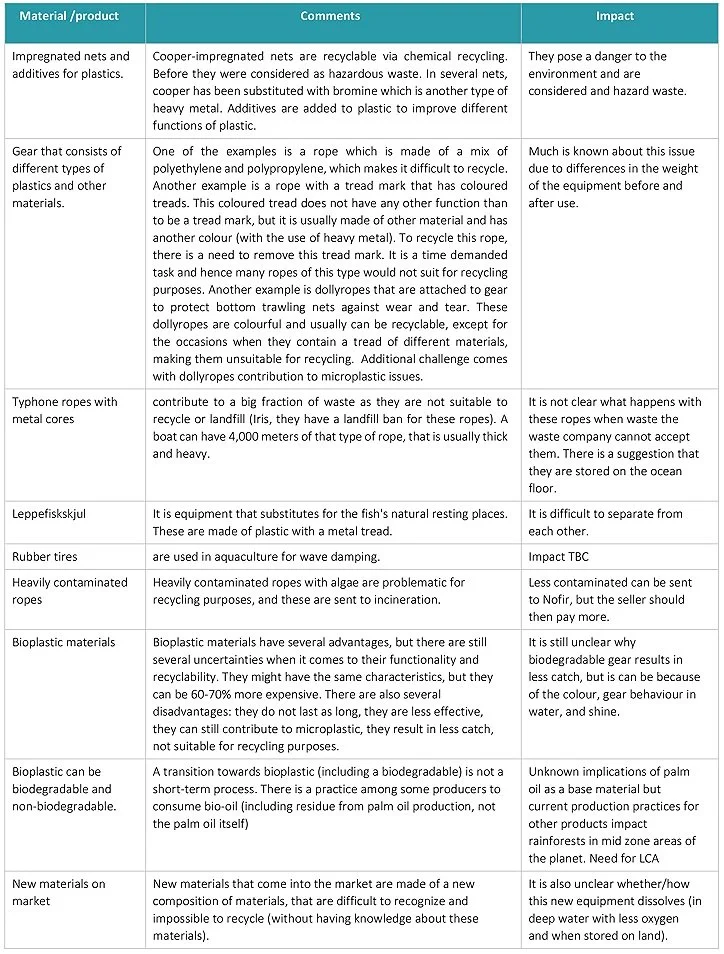

Table 2: Table 2: Problematic areas for fishing and aquaculture gear

Ways Forward

There are several solutions to the above indicated issues (recourses, procurement and regulations).First and the most radical suggestion is to ban use of mixed materials. However, it is recognized that it is impossible to substitute all the problematic materials/gear in a short term. The quality of locally produced ropes is easy to control, rather than ropes coming from Asian countries.

Second, support the use of homogenous materials, such as nylon (which can be recycled to econyl) nets or HDPE pipes are easy to recycle. However, another issue with HDPE feeding pipes is their contribution to microplastic, since pellets with food are transported with a use of air. However, using water instead of air in pipes will probably generate less microplastic. So microplastic issues should be studied not only from the perspective of the material composition but also from the perspective of methods used in aquaculture. Another possibility is to use other or homogeneous materials for dollyropes.

Third, decisions on substitution of existing materials should evaluate the EOL (LCA and MFA) and the impact they can have on the recycling aspect of the product e.g., impact on current processes and quality of recyclate production. The design of the new products and equipment, in addition to improving the product performance in its primary role should optimise the secondary product use each item. This must include the most sustainable route for each product and the optimisation of recycling. Whilst upcycling, reuse and recycling keep a product in use for as long as possible and is a high priority for circularity, establishing the most sustainable route requires a full LCA to ensure the ‘right decision’ is evidenced.

Finally, the users should demand equipment made of materials that are more suitable for recycling purposes. Fishermen would like to market their products that are caught sustainably with the use of sustainable materials, but they do not want to risk their income if new equipment is not sufficient. A possible outcome is the ability to influence research and development in this field. However, more environmentally friendly equipment and gear can be more expensive.

Quality control measures

All products sold on the market should have a data sheet that provides an overview of the material composition.

In aquaculture, the quality of equipment is strictly regulated. However, if the net, is made of a material that is not recyclable in the first place, then it will still not be recyclable when it is repaired.

As for fishing gear, a challenge comes with the size of the gear. For example, a large fishing seine can be as long as several international football pitches. If during repair the inserted part will be of different material, then it should be dismantled, and the quality should be checked before it can be recycled.

The quality and material composition check are a practice adopted by Nofir. With use of a plastic scanner, Nofir tests the material composition of nets during their dismantling.

General information: key things that may be of importance (RRR and EOL considerations)

Importance of MFA and LCA when developing new materials or substituting the old ones.

Users demand more environmental-friendly equipment that can be also recycled.

It is important to identify the value chain that the recycled plastic can enter and what types of products can be produced. These new products should substitute the production of products that still use virgin oil-based plastic.

Post-oil plastics. How do new materials fit the same purposes as oil-based plastics?

Plastic/gear production in Norway to ensure better quality control (Selstad produces ropes in Norway). The question is if we can produce plastic in Norway for aquaculture.

EU Regulations and Green Deal set many frames for materials and recycling processes. However, there should be more focus on what materials can be used together to increase the possibility to recycle gear and equipment: “design for recycling”.

The importance of going beyond technical advances, working long-term for changes in attitudes, values, and narratives.

THEME: GOVERNANCE AND POLICY

Legislative Framework

Acting on – and adhering to – laws and regulation is a key issue and challenge. A legislative framework that takes into account the shared network responsibility for dealing with the issue of plastics, is considered important. This would then be a common ground for a governance ‘motivating’ governance approach, that fosters communication between actors within industries and between industries.

Defining Concepts

There is a general need to introduce circularity into various acts and regulations. A more fundamental challenge for legislation, however, is the need to standardise the concepts of bioplastics and circularity, respectively. Furthermore, legislation should address both existing and new materials for fishing- and aquaculture gear. To this end, legislation should both limit plastic use and encourage the use of new materials. Requirements and standards for the amount of recycled materials in new products is an important issue in this respect.

Governance with knowledge

Laws and regulations should be based on a precautionary principle. But successful governance also requires knowledge-based management and political will. The EU taxonomy is an important (and detailed) backdrop for developing legislation. The taxonomy related to regulating climate change is also an important framework in this respect, when focussing on circularity as a concept. While it is important to regulate collection points for waste, it was pointed out as a challenge that the Extended Producer Responsibility is focussed on waste collection, not recycling. It was pointed out that “kontrollforskriften” is lacking a reference to fisheries and aquaculture industry.

Governance And Leadership

A governance system should have several concurrent objectives. A main target is to reduce the loss of fishing gear in the ocean, as well as the amount of plastic waste in landfills. To this end, reducing the production of virgin plastics is considered important, as well as promoting gear designs for circularity and longevity. Regulating across the value chain is an important governance aim (taking into account material flow analyses as regards plastic waste collection), although special attention should be given to the design phase and the EOL phase. Furthermore, attention should be directed at harmonizing reporting standards between EU and national regulations.

Balancing the need for change, and the need for a stable/predictable governance system should be an overall objective.

The opportunities for developing business models (at the strategic level) stems from the fact that value chains are seen as symbiotic, i.e., possibilities for business development is found in the connections between fisheries/aquaculture and other sectors. It is also pointed to that currently, the customers of the aquaculture industry value proper waste handling higher than the industry itself. Herein lies unexplored opportunities for business models.

Culture of Knowledge

Building a culture for knowledge coordination is seen as prerequisite for good governance, this is, nevertheless, something that’s not easily institutionalised. In terms of practical governance tools, the industry in particular calls for a balance between incentives and sanctions for undesirable practices. Systems of taxation is central to this. Some pointed out that the introduction of Land rent (“grunnrenteskatt”) has led to uncertainty and less focus on research and development. Tax reduction schemes when participating in circular value chains can be documented, is mentioned as one possible approach forward. A general simplification of procedures for participating in incentive/subsidy schemes is called for.

Subsidising the collection of other actors/companies’ waste would be beneficial, something which underlines the importance of an increased focus on the traceability of lost fishing/aquaculture gear. However, incentives for the storage of waste are also needed. The Port Reception Facility directive would be one area to look at in this respect. Returnable deposit fees connected to port facilities could also be something to consider. More specific demands should also be put on waste companies.

Hopefully, a producer responsibility scheme will cover the costs of recycling fishing gear that is not economically viable today. Reducing the cost of easy to recycle products, while introducing higher fees for non-recyclable products is an option.

THEME: ROLES AND RESPONSIBILITIES

Knowledge creation and knowledge sharing

In order for actors across the value chain to better fulfil their roles and responsibilities, there is an urgent need for more knowledge about the environmental consequences of different industry practices, and for this knowledge to be made accessible to all actors. At present, even when knowledge exists, it is often ineffectively shared. For example, it can be very difficult for a fisherman to assess and compare the environmental impacts of different products when making purchase decisions. In order to make the information relevant to such decisions accessible, more standardization is needed. If a product is required by law to include standardized indicators of its total environmental impact across the value chain, fishermen can make informed decisions. Traceability of measurements is also important in order for data to be transparent and trustworthy.

A public body could take an active role in organizing knowledge dissemination across the value chain. Public bodies must also improve their collection of primary data, for example about the origins of the waste they collect.

Actors from academia potentially play a vital role in creating and sharing knowledge. As observers from outside industry and government, they are in a better position to adopt a holistic view of the value chain than actors focused on their own narrow role within it. Academic research should focus on holistic solutions and strive to become more practice-oriented.

A lot of tacit knowledge exists in the fishing industry. For example, many fishery practices are handed down from generation to generation or transmitted verbally among fishermen but not codified or widely shared. Academics could play a role in gathering and codifying some of this tacit knowledge and make it more accessible.

Coordination and collaboration

There is a need for better coordination and collaboration among all actors in the value chain. Government regulatory agencies often neglect to communicate with one another. One solution for this could be to set up a new overarching body or mechanism to connect and coordinate the different agencies. A mentality change in the direction of holistic thinking is also needed among the regulators.

In fact mentality change is needed across the ecosystem: in public waste companies, in industry, and among fishermen. Sometimes fishermen lack confidence in waste collection systems on land because of a lack of knowledge or negative experiences in certain harbours; waste companies could actively help to build trust with fishermen by providing them with better information. Industry actors must adopt a proactive attitude to participating in environmental discussions.

Collaboration between academia and practitioners should be strengthened. Academics are often distrusted by practitioners and vice versa. The key to building trust is to organise more collaborative projects involving academics and representatives from the fishery and aquaculture sectors.

Incentives and regulation

There is a high willingness in the industry to adopt new, environmentally friendly technologies, but cost is a barrier. Regulators should encourage adoption of such technologies by providing economic incentives, e.g., tax incentives. At the same time, industry structure is changing in the direction of more consolidation and more foreign owners. Remotely based owners may not feel the same obligation to support the local community as local owners have traditionally done; new regulation may be necessary to encourage responsible governance

Incentives are also relevant in public sector institutions. Local monopolies on waste management are a barrier to innovation; regulation should favour more competition. The “self-cost principle”, which dictates that public waste management companies charge fees that exactly cover their costs, should be modified so as to provide better incentives to control costs and pursue innovation.

Academics should be incentivized to reach out to practitioners and bridge the gap between academia and industry. For example, university researchers could be required to devote a certain amount of time and resources every semester to collaborative projects with practitioners.

Finally, regulators should keep in mind that pursuing economic growth at any cost is a reckless policy. Regulation aimed at slowing growth in specific sectors, including the fishery and aquaculture sectors, may be necessary for the sake of protecting the environment.

Business innovation

Business innovation has the potential to cut across the themes above and strengthen knowledge sharing, coordination, and incentives. Leasing is a business model with potential for expansion, as it can theoretically improve resource use and accountability compared to the dominant model of users owning their equipment outright. There is an underexploited latent demand for consultancy services focusing on channelling information relevant for decision-making to managers in the fisheries and aquaculture sectors. The judicious use of artificial intelligence and machine learning techniques may help consultants and other information providers transfer knowledge efficiently.

One way of fostering collaboration and a holistic mindset in the private sector is to develop diversified businesses that combine expertise from different parts of the value chain in-house. Helgeland Plast exemplifies this approach

THEME: SOCIETY AND CHANGE

Knowledge and change in attitudes

‘Increasing knowledge and altering peoples’ attitudes, values and narratives go hand in hand.’

Simultaneously as society in general, and fishing and aquaculture sectors specifically, are in urgent need of gaining increased relevant knowledge to sustainable product design, usage and recycling, we also are in great need of attitude changes, and this will take time. Changes in education should thus take place from the early childhood ages until higher education. Because attitude and value changes probably depend on childhood education. However, attitude changes can also take place through the pathway of introducing smaller technical innovations in the fishing and aquaculture industries. For instance, a campaign invented small bags that the fishers could tie to their waists, and that fishers then could use to depose small rope leftovers. These bags facilitated the recycling for these fishers because their need of quick actions when out at the open sea in bad weather was considered. However, these kinds of innovative small campaigns could catalyse larger changes in practices and mindsets about the importance of recycling, the idea is that through new practices we change.

Transitions in the Education System

The educational system further needs to epistemologically change in addition to improving technical education and coursing. We need interdisciplinary thinking to become the standard, Institutes of circularity could be organized, where different sets of questions are posed. New narratives must be facilitated and created about how we approach circularity.

Clear societal communication

Clear communication from governmental agencies and other actors is crucial to enhance recycling practices. A traffic light system could be an element, and also a classification system of repairability, perhaps similar to the energy classification system. Simpler and easy instructions about how to follow regulations and recycle.

A new value system in our societies is in the long term a necessity. For instance, while it must be made profitable to recycle, prolong usage and to design longer lasting products, making it too expensive to have waste, may enhance the risk of people dumping it on the ocean. In addition, putting price on things will probably not be enough; we also need to work on what we value. There is a contraction in a global society where sustainability is the goal, while simultaneously we continue to be and create a society based on competition. To encourage new values, positive associations instead of shame and guilt might enhance the mobilizing effects. Along with new values, stronger orientations towards empathy must be cultivated.

Visibility of decision making, choices and social justice

‘Reducing distance to increase visibility of choices made (or not made) and to enhance social justice’

Distance, either geographical or else, to the consequences of ones’ actions is a hindrance to making good and sustainable choices. Exposing individuals and society to the visuals, smells, and narratives of environmental disasters or malmanagement of plastic leftovers is an important step to generate awareness and alter behaviour and choices.

When this is not possible, other possibilities are there to increase visibility. When a consumer buys a product, the product could have a label facilitating visibility about whether materials used are recycled or not. This is an important factor to generate consumer awareness, however, it needs to be preceded by educational changes (see first theme), so that individual consumers and collective entities can critically assess whether the labels provide good enough information or not, because there is always a risk of ‘green washing’. New directives against greenwashing are coming from the European Union, but it will take some years before implementation in Norway. In Norway, municipalities and counties need to be made financially, and in terms of broader competences, ready to monitor the aquaculture sector, and whether such as old cages are in fact recycled or stocked in bays where pollution probably occurs. It is not easy for municipalities with pressured economies to be able to engage properly in these kinds of monitoring activities.

Connected to this idea, there is a risk when substantial improvements happen locally, that we get a ‘displacement effect’, relocating environmental damages or social suffering elsewhere. For instance, increased accountability in Norway, could lead to the altering of value and supply chains, possibly making impoverished people lose their employments elsewhere. Thus, changes must have a global social justice scope, even if extremely complex to gain knowledge about every aspect of change in the value chain. LCA and MFA are very important and must be strengthened, and also made available to customers and society in general.

CREATING TRANSITION PATHWAYS

DESIGN hierarchy and approach

1. Develop a smart system and management protocols Transitioning to more circular practices is an evolutionary process. To build the correct strategic and operational bodies, adequately develop knowledge and data in support of this change, and the systems required to enlist the right kind of decision making takes time. Much of what we know today may well change in the near future, therefore establishing a learning system suitable to reflects and adapt to systemic change is required. This requires a conceptual framework of the system, shared learning and insights from other systems, Digital Product Passport (DPP)or EPDs of all products and services, relevant and supporting legislation & guidance (e.g., fully sketched out parameters and guidance on EPR etc, and the ability to achieve processes & system gains (data access & knowledge development).

2.Develop operation guidance in tandem with developing a smart system for circular economic change a number of tools are required to act as guidance. This includes carefully linked regulatory services to the strategic aims of the smart system, the associated development of CE support mechanisms, appropriately set laws, that are reflected by, and actioned through, suitable tariffs and incentives.

3.Develop infrastructure and support systems, at the practical level the strategic and operational system(s), parameters and associated guidance must engender suitable action in key areas current seen as ‘high priority’ in the pursuit of circular practices for the sectors. These include increasing the availability of suitably monitored repair facilities, by this we mean those which adhere to best practices and not cheaper less circular options. Improved EOL collection, EOL separation facilities which follow waste hierarchy protocols and optimise the best route of action for sector waste. National best practice guidelines are required with suitable monitoring bodies – these should learn from current best practice in market leaders in RRR, incineration, etc. Only the optimised routes for circular practise should be selected based on LCA/MFA supported DDP/EPDs e.g., Collection avenues – RRR options (mechanical, chemical, eco-industrial network).

4. System feedback loops: the system should ensure consistent and accurate feedback is embedded in the smart systems structure, representation of key sectors, and progressive evaluation systems inform decision making and system updates as required. Establishment and governance of the system should be transparent, collaborative and reflexive of key circular economic principles addressing both current and future needs in keeping with national and global SDA criteria.

MATERIALS

1. Quality, lifetime and knowledge: A customer should have knowledge about the material composition and what recycling opportunities gear or equipment have. Knowledge about and control of products and materials can be achieved through control and compliance and possibility to avoid usage of mixed materials. Control and compliance of what is bought and a check on whether the material is suitable for recycling can be done through guidance (by Producer Responsibility Organization, fishers' organizations) and supervision and control (by the government).

2. Additives for plastics: There is a need to map what roles and functions additives have and how they affect the environment (via LCA and MFA). Toxicological analysis and governmental control and restrictions are important at this stage. The question is how to regulate additives that have a function to prolong the use of equipment and protect the cover material against aging. Here the role of R&D and policy mechanisms are important for both fisheries and aquaculture. More research is needed both on material components and plastic/biopolymers, additives, and replacement options, including the possible use of natural components (e.g., vitamins, and natural organic compounds).

3. Fees and incentives to increase circularity rate (policies): Any fee introduction requires a quantification of the harmful effects in order to defend the fee. Incentives can be introduced at the production stage. For example, the manufacturers who produce gear that are easy to recycle, can get a lower remuneration, compared to producers who do not consider recyclability. Eco-modulating in EPR, means that it is more expensive to produce problematic gear than gear that is easy to recycle (Eco-modulation of the remuneration for producer responsibility). Furthermore, it can be necessary to ban composites equipment with toxic anti fouling additives. The challenge with a ban is a possible absence of good alternative products i.e., the production of new material can be much worse for the environment than the actual use old material. It is important to have knowledge about substitutions before banning a specific material.

4. Customer’s demands for recyclable equipment: Customers can demand equipment that is more suitable for recycling purposes. However, this demand is also controlled by the material price and quality. The transition should be knowledge based in order to do the right thing the second time around. The government can also play a role here. The authorities may set requirements for public procurement, (for example, the material you buy must be as much reusable/recyclable as possible).

5. Innovation and research: are needed for recycling technology and prefer the one that can assist high-end products. There are three different recycling types: mechanical, chemical and thermal. The question is how these existing methods can contribute to the high-end product or to the production of new gear that complies with certification requirements and standards.

6.Measuring success: To measure that the above-mentioned stages to evaluate whether the vision/goals have been reached, it is possible to implement environmental monitoring (via authorities and/or industry) and target indicator (for example lifetime of gear, volume for landfill and incineration, and percentage of recycling plastic in new gear).

GOVERNANCE AND POLICY

1. Governance in general: Governmental bodies key role is to ensure that the framework of relevant laws and regulations are amended, and that monitoring schemes are implemented.

2. Funding the design phase of the value chain. Government bodies have an important role in funding the research and development of new materials. An effective development relies on a partnership between industry driven R&D and Science partners, however.

3. Industry commitment. Both the aquaculture and fisheries industries need to commit to a reduced use of plastic materials and must play an active role in the development of new and alternative materials. Such commitments are not forged only through a regime of governmental sanctions, but also depends on the introduction of incentives for adopting new practices and contributing to material development. While governance institutions are sensitive to the demands of the general public, industry actors rely on the demands and preferences of their customers. This probably points to an important role for the governance institutions in shaping customer expectations to the use of plastic materials and their substitutes. The “system to be governed” also need to take the waste companies into consideration, as a key actor in dealing with circularity.

4. Flexibility, evaluation, and adaptation. New regulations and incentives aimed at modifying current practices among industry partners need flexibility when introduced. It is important that new governance instruments are routinely evaluated for effects to be assessed, and adjustments to be made, if needed. Again, collaboration between governance institutions and industry partners is important. Regulations and incentives should be sensitive to not being perceived as “unfair” and have a universal appeal, securing industry commitment and the adaptation of practices.

5. Industry responsibilities. New governance instruments, whether regulatory or incentive building, imply some common responsibilities among the industry’s activities that needs highlighting. Documenting and reporting on circular practices and mitigating the use of plastic materials is important for evaluating and adapting the introduction of new governance instruments. While challenges related to material design would be a prime focus for both the aquaculture and fisheries industries in this respect, the issue of logistics should be considered as the most pressing issue for the waste companies. Governmental institutions main task is that of controlling and “auditing” the industry as a part of the evaluation process.

ROLES AND RESPONSIBILITIES

1.The vision is a value chain that is well-coordinated and transparent and characterized by clearly defined roles and responsibilities, a value chain in which each individual actor has both the knowledge and incentives necessary to make decisions that minimize environmental costs. At present, information asymmetries between different stakeholder groups complicate the adoption of new, environmentally friendly technologies. For example, it can be difficult for fishermen to assess the environmental footprint of different types of fishing gear because the information is not available to them in an easily accessible format. Meanwhile, elsewhere in the value chain, siloed thinking among regulatory agencies inhibits a coordinated approach to regulation, which also reduces efficiency.

2. Government role: In order for the vision sketched above to materialize, government agencies must promote knowledge exchange across the value chain. This can be done by establishing forums where decision-makers from different parts of the value chain can share knowledge and ideas. Another possibility is to sponsor the development of a central, freely accessible knowledge database covering topics such as regulations and the plastic footprint of products. It is hard to guarantee that a centrally created knowledge database will deliver the information users want, but even if it doesn’t, it might inspire others to develop new channels for knowledge sharing. Artificial intelligence (AI), carefully applied, may help to distribute relevant knowledge across the value chain in a user-friendly format.

3. Academic role: Academia can play an important role in a well-coordinated value chain by bridging knowledge gaps among practitioners. The SHIFT-PLASTICS project itself illustrates the role academics can play as facilitators of knowledge exchange. More research funding should be used to incentivize academics to engage more in stakeholder interaction and innovation. Potential contributions by academics include mapping the roles and responsibilities of actors in the fishery value chain and identifying problems and challenges in the sector.

4. Governance and change agency: The problem of regulatory agencies working in silos instead of coordinating with one another can be addressed by introducing a missions-oriented policy to guide their work. Such a policy encourages agencies to work together toward the shared goal of solving one or more societal challenges.

5. Policy and tools: Crucially, the government must use its power to shape the incentives of other stakeholders. This can be done by means such as offering tax subsidies on recycled products, banning certain materials outright, empowering waste management companies to make decisions that improve circularity, and stimulating competition among waste companies to spur value creation.

SOCIETY AND CHANGE

1. LCA and MFA are critical tools: LCA and MFA must be part of all value/ product choices from the beginning. Products must be designed to last longer, and be composed by a larger part of recycled plastic. Governments, producers and customers alike share the responsibility for pushing forward these changes.

2. Labelling of products: Products must be labelled so that consumers/buyers can critically assess MFA and LCA. This is a crucial part of the transparency that is required in order to change the attitudes of producers and customers. Consumers need to have the tools to critically assess these labels, for instance to critically assess when “greenwashing” occurs. This is why education goes along here, through educational changes, we can learn to demand high levels of transparency and how to assess whether the MFA and LCA are good enough.

3. Change of attitudes and values: It must be expensive to not recycle, however not too expensive, as people may dump waste in the ocean. This illustrates the complexity of making sustained and profound change. As long as we do not change our value systems, rules and regulations, we may end up worsening a situation. Again, this is witness to the importance of generating an educational system that promotes critical thinkers, asking different kinds of questions than today.

4. Clear communications and instructions: about how to recycle. Government and producers need to improve communication about recycling so that there are less mistakes or doubts about how to do it, and how this makes a difference.

6. Expose people to the consequences of not recycling: so we can change mindsets and what we value (open day for schools, other kinds of applied knowledge). Distance reduces empathy and understanding of the consequences of certain choices. People living in spaces far from where consequences of pollution are felt more severely, may need to be exposed to the realities far from them, in order to change ways of being and doing.

SHIFTPLASTICs Workshop Team

Megan Palmer-Abbs (NRI): WP lead, design and lead for workshop, author & media director

Arild Gjertsen, Jens Ørding Hansen, Julia Olsen, Susanne Normann (NRI):

workshop facilitators, analysis, report co-authors

with Torunn Honsi (WNRI): workshop facilitator

Marta Anna Løvberg (NRI): Videographer

Produced in collaboration with SHIFTPLASTICs project team and partners: